- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- 简体中文

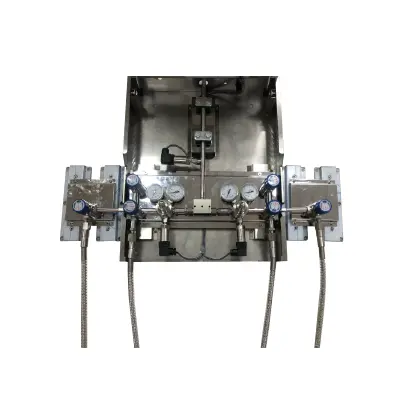

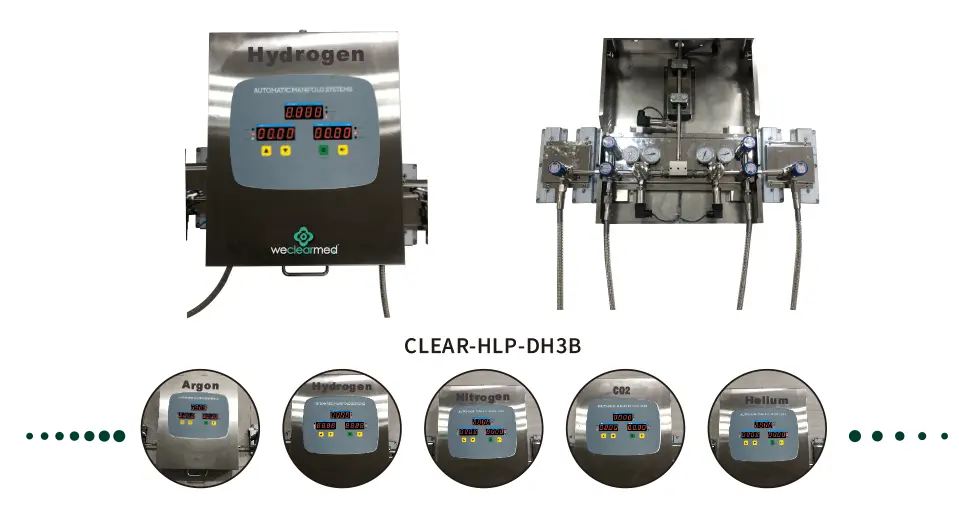

Industrial Manifold

Send Inquiry

CHARACTERISTIC:

1. Bilateral automatic pressure reducing air supply system. Automatic switch,24H continuous air supply.

2. Bilateral exhaust gas purge diaphragm valve group; ensure the purity of the gas used to ensure 6.0 grade

3. The main air inlet control diaphragm valve group is configured on both sides, which is convenient for gas control and system maintenance

4. The material of valve body and valve cartridge as are made of stainless steel 316L

5. The pressure reducing valve and diaphragm valve shall be made of Hastelloy C276

6. The Industrial Manifold components are cleaned by ultrasonic to ensure that there will be no secondary pollution of high-purity gas

7. Meet the use of oxygen, nitrogen and methane. Also the heating molde of carbon dioxide and nitrous oxide.

8. The maximum inlet pressure is 30Mpa/300Bar; the maximum outlet setting pressure is 60Psig or 150Psig (adjustable); the maximum leakage rate is 1*10-8mbar I/s He

9. Independent power box, strong and weak power separated, high safety level, input power supply AC220V/110V dual voltage auto, DC24V safety control voltage

10. Pressure digital display, monitor the air supply pressure on both sides, output pressure; sound and light alarm will sound when fault;

11. Precision explosion-proof pressure sensor, real-time reading pressure value, induction without lag, transmission without distortion

12. Standard MODBUS-RS485 serial port for networking, which can transmit real-time pressure and oxygen flow data and alarm information to the medical gas central monitoring and alarm management system through the network; it can provide external output switch function