- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- 简体中文

Medical Copper Pipes

Send Inquiry

1. High purity gas transportation guarantee

Material purity: Medical Copper Pipes should meet ASTM B819 standard (copper content ≥ 99.9%), to avoid the precipitation of impurities contamination of oxygen.

Surface finish: the roughness of the inner wall is ≤0.8μm (Ra value), which reduces the resistance to gas flow and residual particles, and meets the cleanliness requirements of ISO 7396-1 for medical gas pipelines.

2. Anti-oxidation and corrosion resistance

High-pressure oxygen environment: Copper generates dense oxide film (CuO/Cu₂O) in high-pressure oxygen, preventing further oxidation, withstanding pressure range of 0.4~1.5MPa (GB 50751 specification).

Resistant to chemical corrosion : Resistant to chlorine-containing disinfectants (such as sodium hypochlorite) and medical alcohol wiping, service life of up to 30 years or more (European EN 13348 standard verification).

3. Inhibit microbial growth

Copper ion antimicrobial mechanism: by releasing Cu²⁺ to destroy the bacterial cell membrane (e.g. the inactivation rate of Pseudomonas aeruginosa>99%), in line with the requirements of YY/T 1778.1-2021 “Antimicrobial Performance of Medical Gas Pipeline”.

Clinical verification: UK NHS data show that copper oxygen piping reduces ICU infection rate by 42% (compared with stainless steel piping).

4. High sealing and safe connection

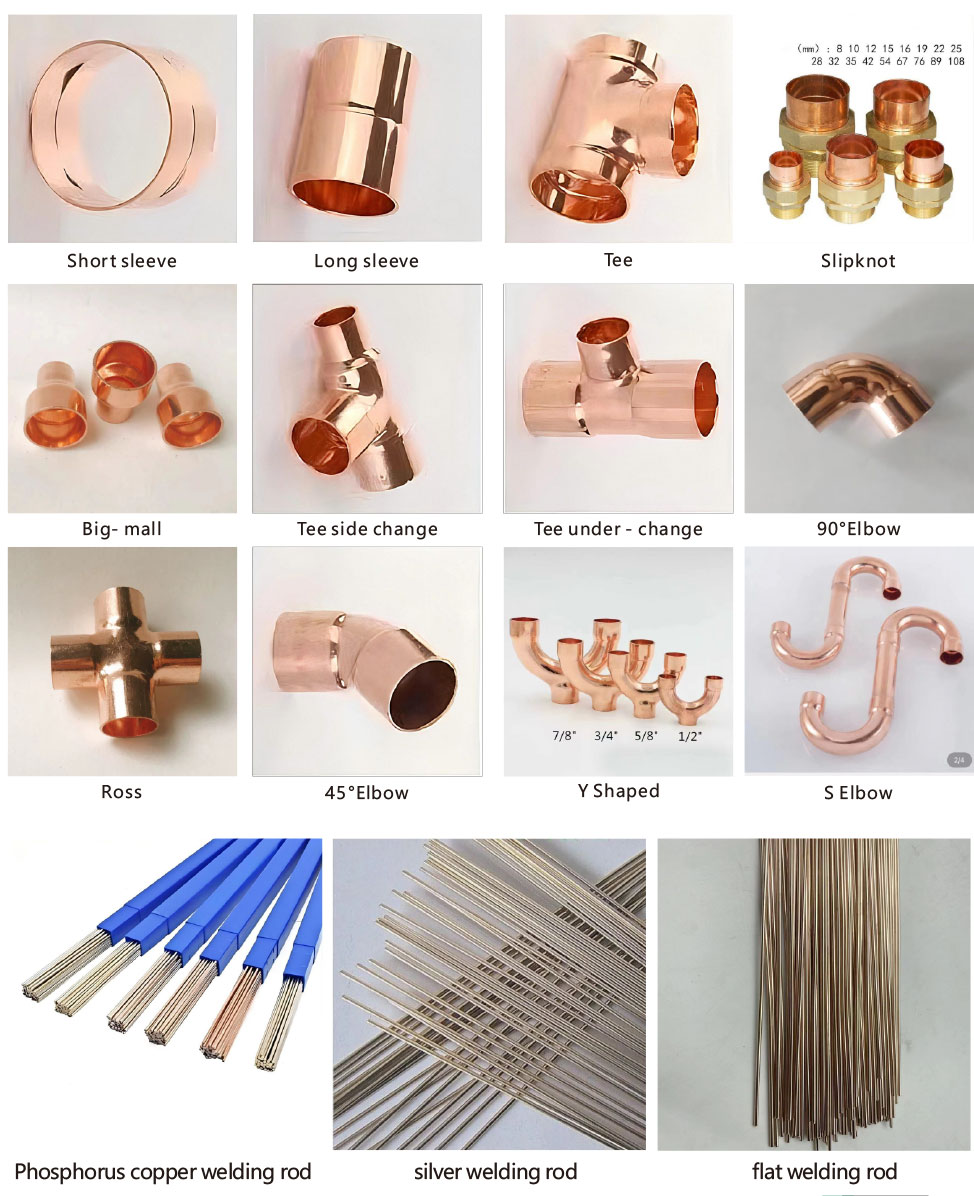

Welding process : Silver-based brazing (Ag-Cu-P alloy, melting point 650~800℃), weld strength of more than 95% of the base material, helium leak detection rate <1×10-⁹ mbar-L/s.

Anti-leakage design: low coefficient of thermal expansion of copper tube (16.5×10-⁶/°C), low temperature deformation, avoiding the risk of oxygen leakage caused by loose interface.

5. Excellent mechanical properties

Pressure resistance: annealed copper pipe burst pressure ≥ 25MPa (ASTM B88 standard), far more than the working pressure of medical gas system (usually <1.6MPa).

Flexibility: cold bending to a radius of ≥ 3D (pipe diameter) without wrinkles, suitable for complex building structure wiring (such as vertical piping between hospital floors).

6. Anti-static and fire safety

Conductivity: the resistivity of copper is only 1.68×10-⁸Ω-m, avoiding the accumulation of static electricity triggered by oxygen combustion and explosion (in line with NFPA 99 fire code).

Flame retardant: melting point 1083 ℃, much higher than plastic pipes (such as PVC ignition point of only 260 ℃), fire is not easy to melt and collapse.

7. Economy and Sustainability

Total life cycle cost: Although the initial cost is higher than stainless steel, the maintenance cost is 50% lower (no coating aging, no frequent disinfection).

Recycling value: 100% recyclable, in line with green hospital construction standards (e.g. LEED v4.1 material recyclability score).

Typical application standards

International standards: ISO 7396-1 (medical gas piping system), DIN 1054 (copper pipe material requirements).

Domestic standard: GB 50751 “Technical specification for medical gas engineering” clearly requires the use of copper pipe (wall thickness ≥1.5mm) for oxygen main pipeline.

| Number | Product Name |

External diameter |

Thickne SS |

Style Status | length | KG/M | Material |

| 1 |

Medical degreased red copper pipeline |

6mm | 1.0mm | coiled material | 350 | 0.1400 |

(GB-YS/T 650) |

| 2 | 6mm | 0.8mm | coiled material | 430 | 0.1165 | ||

| 3 | 8mm | 1.0mm | coiled material | 250 | 0.1960 | ||

| 4 | 8mm | 0.8mm | coiled material | 310 | 0.1613 | ||

| 1 | 10mm | 1.0mm | coiled material | 200 | 0.2520 | ||

| 2 | 10mm | 0.8mm | coiled material | 240 | 0.2061 | ||

| 3 | 12mm | 1.0mm | coiled material | 160 | 0.3080 | ||

| 4 | 12mm | 0.8mm | coiled material | 200 | 0.2509 | ||

| 5 | 15mm | 1.0mm | Straight Pipe | 6 | 0.3920 | ||

| 6 | 15mm | 0.8mm | Straight Pipe | 6 | 0.3181 | ||

| 7 | 16mm | 1.0mm | Straight Pipe | 6 | 0.4200 | ||

| 8 | 16mm | 0.8mm | Straight Pipe | 6 | 0.3405 | ||

| 9 | 19mm | 1.0mm | Straight Pipe | 6 | 0.5040 | ||

| 10 | 19mm | 0.8mm | Straight Pipe | 6 | 0.4077 | ||

| 11 | 22mm | 1.0mm | Straight Pipe | 6 | 0.5880 | ||

| 12 | 22mm | 0.8mm | Straight Pipe | 6 | 0.4749 | ||

| 13 | 25mm | 1.0mm | Straight Pipe | 6 | 0.6720 | ||

| 14 | 25mm | 0.8mm | Straight Pipe | 6 | 0.5421 | ||

| 15 | 28mm | 1.0mm | Straight Pipe | 6 | 0.7560 | ||

| 16 | 28mm | 0.8mm | Straight Pipe | 6 | 0.6093 | ||

| 17 | 35mm | 1.2mm | Straight Pipe | 6 | 1.1357 | ||

| 18 | 35mm | 1.0mm | Straight Pipe | 6 | 0.9520 | ||

| 19 | 38mm | 1.5mm | Straight Pipe | 6 | 1.5330 | ||

| 20 | 38mm | 1.2mm | Straight Pipe | 6 | 1.2365 | ||

| 21 | 42mm | 1.5mm | Straight Pipe | 6 | 1.7010 | ||

| 22 | 42mm | 1.2mm | Straight Pipe | 6 | 1.3709 | ||

| 23 | 50mm | 1.5mm | Straight Pipe | 6 | 2.0370 | ||

| 24 | 50mm | 1.2mm | Straight Pipe | 6 | 1.6397 | ||

| 25 | 54mm | 1.5mm | Straight Pipe | 6 | 2.2050 |